一、基本情况

邱新义,男,1987年6月出生,博士,副教授,硕士研究生导师。

主要从事难加工材料(钛合金、CFRP等)切削加工、刀具设计等方面的研究工作。主持国家自然科学青年基金1项,湖南省自然科学基金青年项目1项。近年,以第一作者或通讯作者在《Journal of Manufacturing Processes》、《Composite Structures》、《International Journal of Precision Engineering and Manufacturing-Green Technology》、《The International Journal of Advanced Manufacturing Technology》和《宇航材料工艺》等刊物上发表论文10余篇。

二、主要科研特色

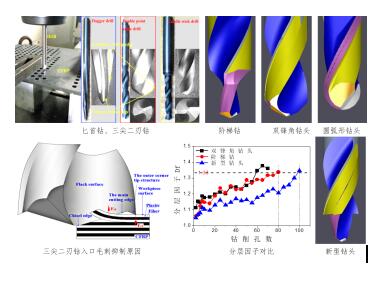

面向CFRP高品质制孔需求,主要开展了CFRP切削机理、低缺陷制孔刀具设计等研究。通过全纤维切削角的正交切削实验,揭示了不同纤维切削角下的纤维断裂机理。研究了匕首钻、阶梯钻、双锋角钻头和三尖二刃钻等加工CFRP的性能,并设计了新型复合钻头,结果表明匕首钻和阶梯钻能有效减少轴向力,三尖二刃钻能有效抑制毛刺形成,新型复合钻头能有效减少CFRP钻削损伤。

钻头结构对CFRP钻削质量的影响

三、代表性项目

[1] 国家自然科学基金青年项目,52105442,基于切削力空间分布精准控制的CFRP传动轴管面钻削缺陷抑制策略,2022/01-2024/12,30万,主持

[2] 湖南省科技厅, 湖南省自然科学青年基金项目, 2022JJ40152, 面向CFRP管面高品质钻孔的缺陷形成机理与实现方法研究, 2022-01 至 2024-12, 5万元, 在研, 主持

四、代表性成果

[1] Xin-Yi Qiu, Peng-Nan Li, Ling-yan Tang, Chang-ping Li, Qiu-Lin Niu, Shu-Jian Li, Si-wen Tang, Tae Jo Ko. Determination of the optimal feed rate for step drill bit drilling CFRP pipe based on exit damage analysis, Journal of Manufacturing Processes, 2022, 83: 246-256

[2] Xin-Yi Qiu, Zhen Yu, Chang-ping Li, Qiu-Lin Niu, Shu-Jian Li, Peng-Nan Li, Tae Jo Ko. Influence of main cutting edge structure on hole defects in CFRP/titanium alloy stacks drilling[J]. Journal of Manufacturing Processes, 2021, 69: 503-513.

[3] Xinyi Qiu, Pengnan Li, Changping Li, Qiulin Niu, Anhua Chen, Puren Ouyang, Tae Jo Ko. Study on chisel edge drilling behavior and step drill structure on delamination in drilling CFRP[J]. Composite Structures, 2018, 203: 404-413.

[4] Xinyi Qiu, Pengnan Li, Lingyan Tang, Changping Li, Lintao Xiang, Shujian Li, Siwen Tang, Tae Jo Ko. Formation mechanism of CFRP pipe concave drilling defects, The International Journal of Advanced Manufacturing Technology , 2023, 127: 3557-3567

[5] Xinyi Qiu, Pengnan Li, Changping Li, Qiulin Niu, Anhua Chen, Puren Ouyang,Tae Jo Ko. New Compound Drill Bit for Damage Reduction in Drilling CFRP[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2019, 6:75-87.

[6] Xinyi Qiu, Pengnan Li, Changping Li, Qiulin Niu, Shujian Li, Tae Jo Ko, Lingyan Tang. Tool life evaluation of CFRP drilling with three kinds of drill, Journal of Mechanical Science and Technology, 2022, 36(7): 3643-3651

[7] Xinyi Qiu, Pengnan Li, Qiulin Niu, Anhua Chen, Puren Ouyang, Changping Li, Tae Jo Ko. Influence of machining parameters and tool structure on cutting force and hole wall damage in drilling CFRP with stepped drills[J]. International Journal of Advanced Manufacturing Technology, 2018, 97: 857-865.

[8] Pengnan Li, Xinyi Qiu, Changping Li, Qiulin Niu, Anhua Chen, Tae Jo Ko. Hole exit damage and tool wear of drilling CFRP with double point angle drill[J]. Journal of Mechanical Science and Technology, 2019, 33(5):1-8.

[9] Pengnan Li, Xinyi Qiu, Lina Zhang, Siwen Tang. Study on serrated chip formation andtool wear of cermet tools for milling stainless steel 3Cr13Cu[J]. International Journal of Advanced Manufacturing Technology, 2015, 77: 461-467.

[10] Peng-nan Li, Xin-yi Qiu, Si-wen Tang, Ling-yan Tang. Study on dynamic characteristicsof serrated chip formation for orthogonal turning Ti6Al4V[J]. International Journal of Advanced Manufacturing Technology, 2016, 86: 3289-3296.

[11] 邱新义, 李鹏南, 牛秋林, 李树健, 李常平, 唐玲艳. CFRP管面钻削缺陷形成机制, 复合材料学报, 2023, 40(1): 141-150

[12] 邱新义, 李鹏南, 陈安华, 牛秋林, 黄文亮. 三种钻头钻削CFRP轴向力的时变曲线及预测[J]. 宇航材料工艺, 2018, 48(6): 63-67.

[13] 邱新义, 李鹏南, 陈安华, 牛秋林, 刘峰. 三种钻头钻削CFRP的制孔损伤对比[J]. 宇航材料工艺, 2019, 49(1): 68-71.